HEAVY IRON NEWS

How Eagle Ford Used Data To Advance Completions

Through the appraisal of several datasets, a data-driven network model has been created to minimize costs and maximize production throughout the Eagle Ford Shale. Not only does the model yield some insight into the optimization of completions and fracture treatment designs, but it also addresses the challenges associated with the designing of fracture stimulation jobs for a play.

The database model to locate production drivers that possess the same characteristics of the Eagle Ford Shale. The data is then used to plan effective strategies for completion and stimulation that will allow the return on investment to be maximized.

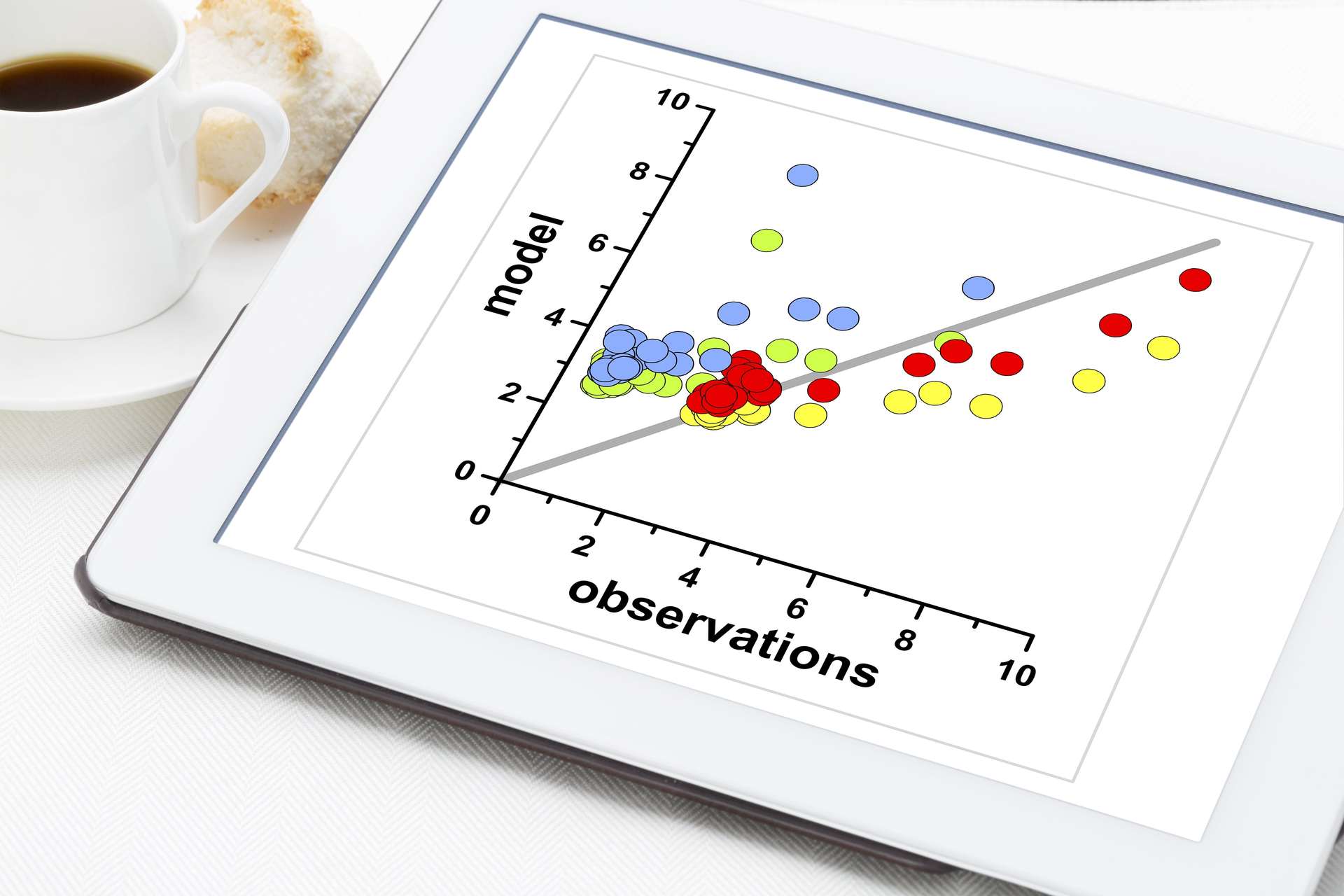

The ANN (artificial neural network) model has been trained on a database and is capable of identifying casual relationships both fracture- and completion-related inputs. It can also obtain drilling and mud data to determine geological parameters, such as permeability, pressure, and fluid saturation. The model outputs were able to predict and observe best well productive values higher than 0.85 for Mcf/psi, 0.9 for boe/psi, and 0.8 for bbl/psi for a 30-day period.

The ANN model identified the crown of the Eagle Ford Shale from sea level as the most vital consistent parameter related to the reservoir. The next most important parameter was butane and pentane fraction. The model also asserts that deeper walls have a tendency to create more hydrocarbons. The deeper walls completed with fracture stimulation programs and additional frack stages also tend to create more hydrocarbons, according to the ANN model.

This model provides evidence for the dual hypothesis that sand treatments in large volumes not only increase inefficiencies and costs and that the use of 100-mesh sand proppants in oil production is insignificant. However, the model also provides evidence for the correlation between 90-day oil production and the pounds of pumped proppant.

Creation Process of the Model

The Eagle Ford evaluation involved the analysis of diverse well datasets to recognize correlations between input and output variables. The flexible neural network modeling used was capable of sifting through numerous databases to create high-quality analysis. Therefore, the ANN model is based on observed data.

The database used by the Eagle Ford study comprised of about 80 wells, which were completed by Operator A, B, and C. The wells were completed from 2011 to 2014 in the various areas of the condensate, oil, and gas windows. About 40 wells, which Operators A and B completed, were randomly selected to train the ANN model. 23 more wells served as test sets for validation purposes and model selection. The 19 wells completed by Operator C were used for the final evaluation of the ANN model after it was developed and tested because these wells were created in the less favorable areas within the location.

Comparative Frack Analysis

Based on the evaluation of Operator C's wells, the ANN model was able to not only pinpoint under-producing wells, but it was also able to provide operators with recommendations based on data for alternate fracture stimulation designs that have the potential to increase both productivity and profits. This modeling approach is not limited by the possession of limited or immense amounts of data. No matter the size of the dataset, the results will prove to be useful for plays like Eagle Ford, which tend to be emerging and more mature in comparison to other plays.

Subscribe to Email Updates

Recent Post